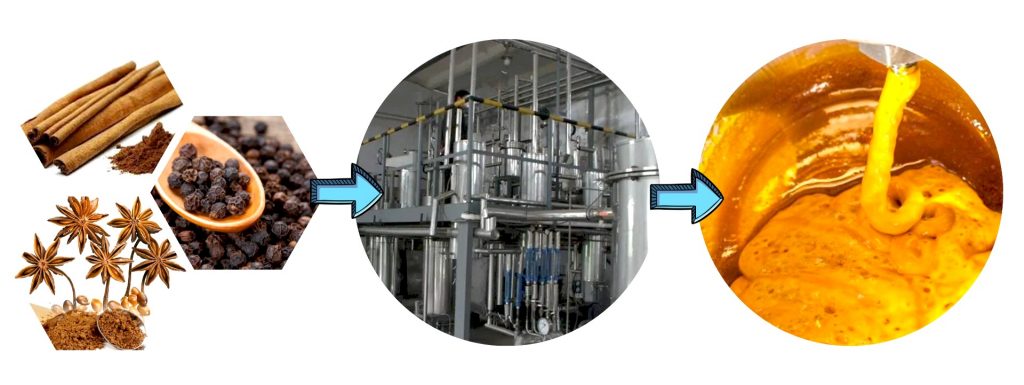

In many developing countries, there is a growing demand to extract plant-based products such as herbs and spices for export. Supercritical CO2 extraction machine is recognized as one of the most advanced and environmentally friendly technologies, delivering high-value extracts without the use of harmful solvents. However, the high investment cost of current systems has limited its wider adoption.

Most commercial CO2 extraction systems are designed to operate at pressures up to 500 bar with complex processes to handle a wide range of materials. This makes them expensive and often unnecessary for herb and spice applications, where optimal extraction conditions are typically between 250–300 bar with simpler operating parameters.

Example: Black Pepper Extraction

- Optimal condition: 300 bar, 50 °C, 5 hours

- Yield: 500 g/L, 5.5% piperine, 2.3% VOC

- Alternative low-pressure condition with our design: 180 bar, 38 °C, 14 hours

- Achieves a comparable yield with significantly reduced system requirements.

This demonstrates that a flexible system design with two pressure levels is more cost-effective:

- 180 bar type: specialized for raw materials with low oleoresin content.

- 300 bar type: used for raw materials with high oleoresin content.

By tailoring the system to the actual extraction needs, investment costs can be reduced while maintaining performance.

| VOC | Piperine* | 300bar | 180bar | |

| Black pepper 500gr/L | 2.3 % | 5.5 % | 5 hours | 14 hours |

| Black Pepper 250gr/L | 3.2 % | 2.2 % | 3.5 hours | 8 hours |

Energy Efficiency Through Heat Pump Technology

With our long-standing expertise in refrigeration system design, we have developed a proprietary heat pump technology that fully replaces traditional heating elements during extraction. This innovation:

- Provides precise temperature control.

- Significantly reduces electrical consumption.

- Enhances overall system efficiency.