Our CO2 extraction technology produces two main product types: essential oils and oleoresins. Each extraction condition is carefully optimized to preserve the full range of valuable plant compounds.

1. Essential Oils

- CO2 Subcritical Extraction (<70 bar)

This process isolates the lightest aromatic molecules (C₅–C₂₂). These molecules deliver a more intense and authentic aroma compared to steam-distilled essential oils (C₅–C₂₀). Subcritical CO₂ essential oils are highly prized for perfumery and premium applications where fragrance quality is critical. - CO2 Select Extraction (~100 bar)

Produces essential oils containing molecules from C₅–C₂₅, with a composition somewhat similar to steam-distilled oils. However, they also include extra volatile compounds that cannot be captured by steam distillation, resulting in a richer and more complete profile.

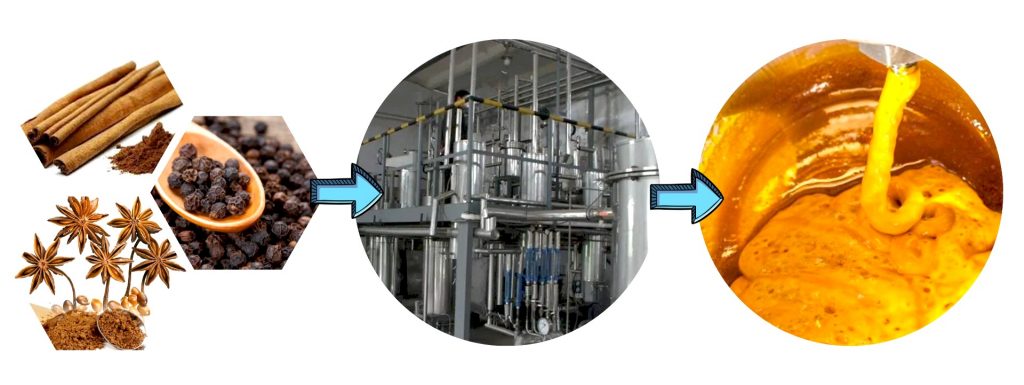

2. Oleoresins

- CO2 Total Extraction (180–300 bar)

This method extracts both volatile and non-volatile components of the plant, including aromatic compounds, resins, fatty acids, waxes, and natural pigments. Molecules typically range from C₅–C₆₀, giving the extract a viscous texture. These oleoresins dissolve well in lipophilic carriers such as essential oils or vegetable oils.- 180 bar type: optimized for raw materials with low oleoresin content.

- 300 bar type: optimized for raw materials with high oleoresin content.

This two-level approach ensures cost-effective system design while maintaining efficiency.

Note: Due to their viscosity, some CO₂ Total extracts may require gentle warming before use.